Work experiences

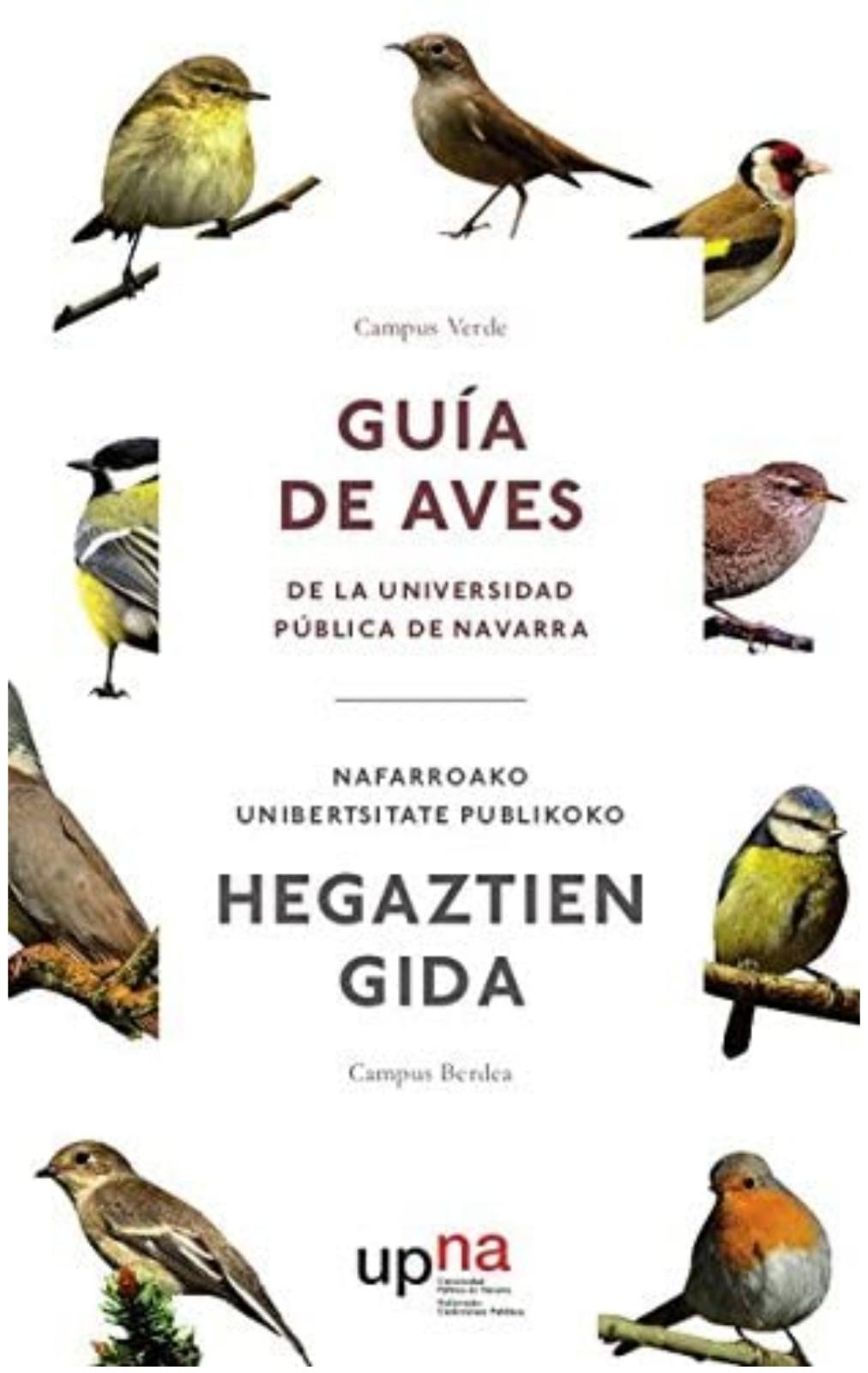

Data processing for Gorosti society. Sociedad Gorosti. (2010-2012)

First experience related to computer science, what I basically did was

developing functions of information analysis, search and correction of

incorrect data, creation of databases and data uploading.

This Mechanical job that provided me the DDBB knowledge I will continue using

during the following years.

In the personal aspect, these jobs I did for SCN Gorosti also got me to realize

that mechanical and repetitive tasks could and should be automated. In the

following years, I will always look to avoid repetitive tasks if they can

be automated, and this became the late motiv of my work.

Final degree project VISCOFAN S.A. (2014)

This project wass drawn up in order to provide solutions regarding the improvement of

energy efficiency of the Cáseda de Viscofan S.A.,

Improvements in lighting will be analyzed and proposed, focusing on the most

conflictive points.

Quality control technician. Wisco Española, S.A (2014-2015)

Once I finished my industrial engineering degree, I found my first career

opportunity as an escholarship engineer on the local job board. I learned

both to work in an office and in a productive plant, to be rigorous at

work and justify my opinions and decisions with data.

Hard skills learned during this year:

-

Production quality control

-

Metrology

-

Chemical and mechanical tests and regulations

-

Parts machining.

-

Claim management and customer service.

Quality Management Assistant. Wisco Española, S.A (2015-2016)

I finished my escholarship and I continued to work at Wisco with added

responsabilities. I was in charge of restarting the laboratory work.

Getting in contact with CAM machine, and tensile testing machine parts.

Getting training and developing the machining program. All the documentation

required (PFEMEA, control guidelines, generation of reports and records) for

the project was drawn up and registered in the system until it was possible

to manufacture and test approved parts.

I also spent part of my time creating a document where NC reports that had

to be reviewed by management were listed and could be easily analyzed.

Quality engineer. ISRINGHAUSEN S.L.U. (2016 - 2022)

Landing a job at ISRI was an unespected opportunity. The team I had the

privilege of helping was tasked with relocating a whole plant production

to another site.

We helped carry out the top-to-bottom new porcesses, new work instructions,

tool purchasing, redefining the quality standards meanwhile production line

by production line were landing in Pamplona. We launched new trazeability systems

and updated old productive systems reducing paper waste. It was not just a

relocation.

The work increased and new colleagues joined our team, in fact, by now we are

working more than twice the people we were at the beggining. As a member of

the relocation team my priorities were:

-

Quality/Process project management.

-

Product quality management.

-

Customer service management.

In 2019 another big project came and I was again lucky to take part on it

with one of the initial members of this adventure. We involved ourselves

in the new product to be industrialized and deployed at plant ISRINGHAUSEN

MADRID. A completly different production system (JIT) had to be revisited

and adapted to the new product.

We went through hard times just after SOP but at the end we achieved what we

had planned with very good results in the present.

Apart from this role in the project I spent two months in 2020 as Interim Quality/Process

manager at ISRI S.A. (Madrid)

Last but not least, over the four years I was able to promote, coach, and

launch the development of many ISRI custom aplications. We started from

scratch and an idea to improve the product quality data handling.

Now we are working on a multi-platform solution that collects, stores, process

and displays all data from a productive line. As a team we now use an agile

metodology, we launched our own development,database and CI/CD servers and

we have deployed our apps in three group facilities.

PM change management Nordex Acciona Windpower (2022 - Today)

New project, new challenges.

I am currently working as a change management engineer for the PM department

at Nordex Acciona.

My main responsabilities are: Coordination of the global change committee ensuring

the best implementation plan.

Coordination of changes in a multi-plant environment and also for PM/EPC changes.

Communicate and ensure that the change notes reported from each global function

are transferred and implemented by the PBOM configuration area in PLM.

Ensure that the change notes are correctly implemented in the PBOM configuration

area.

the implementation project in the different productive areas and

participate in the change management committees.

I am looking forward to learn and grow with this new opportunity.

With passion

Handball

Handball player since I was 11 years old. I have been playing in different categories in BMHuarte and Anaitasuna teams.

Scuba diving

Advanced open water diver. Diving all around the globe and in the Cantabric Sea with Buceo Mistral since 2001. In the last years also with many friends joining this adventure.

Family and Friends